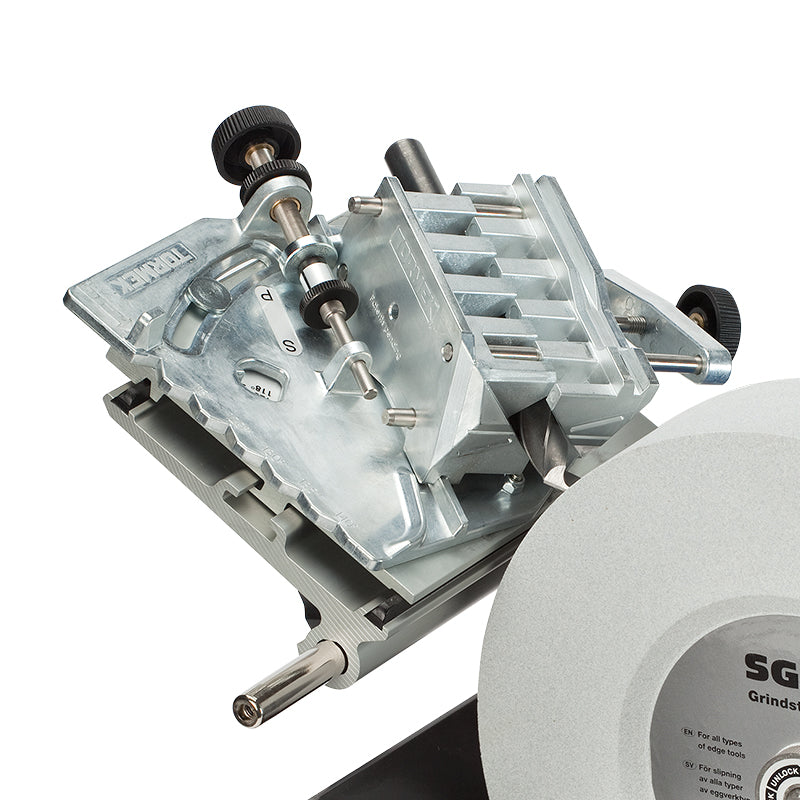

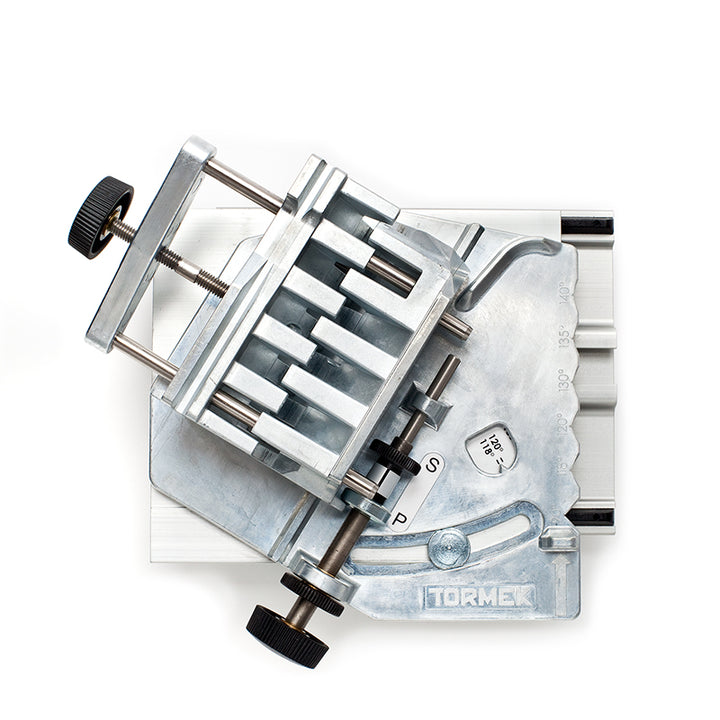

Why DBS-22 Drill Bit Sharpening Attachment?

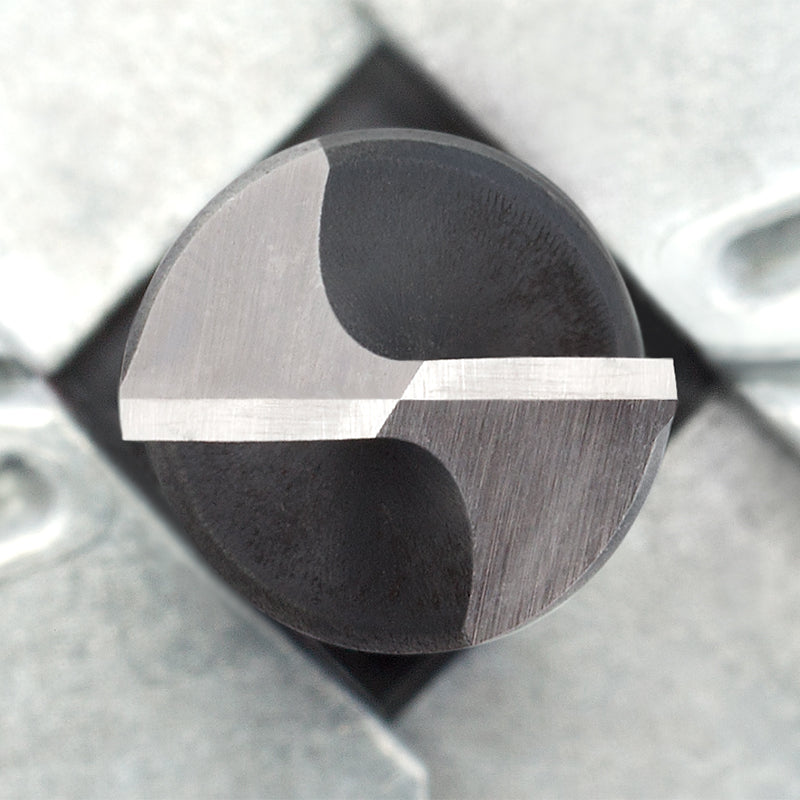

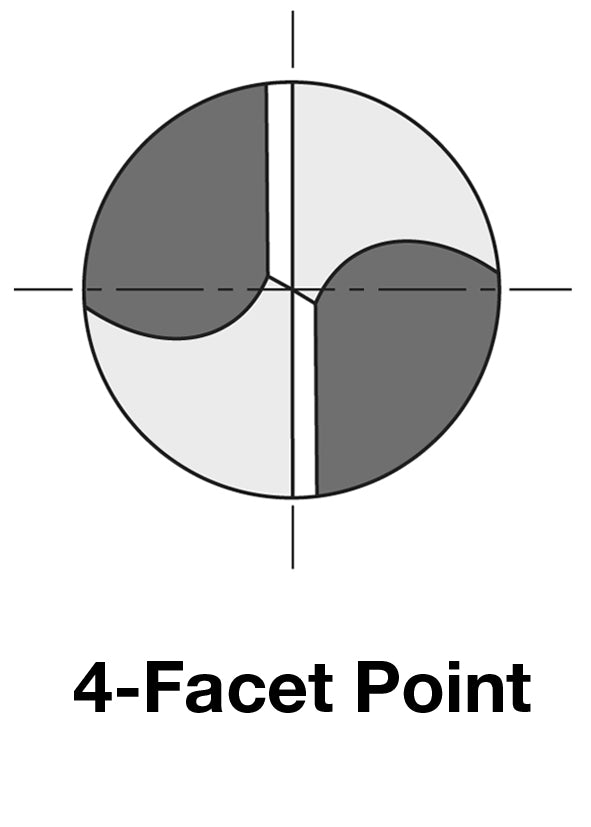

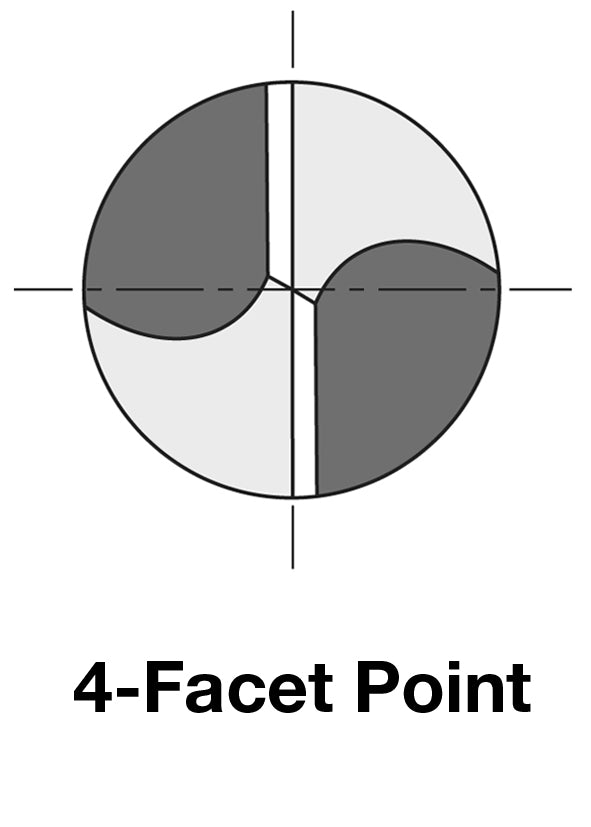

- Sharpens a four-facet point that drills more efficiently and lasts longer.

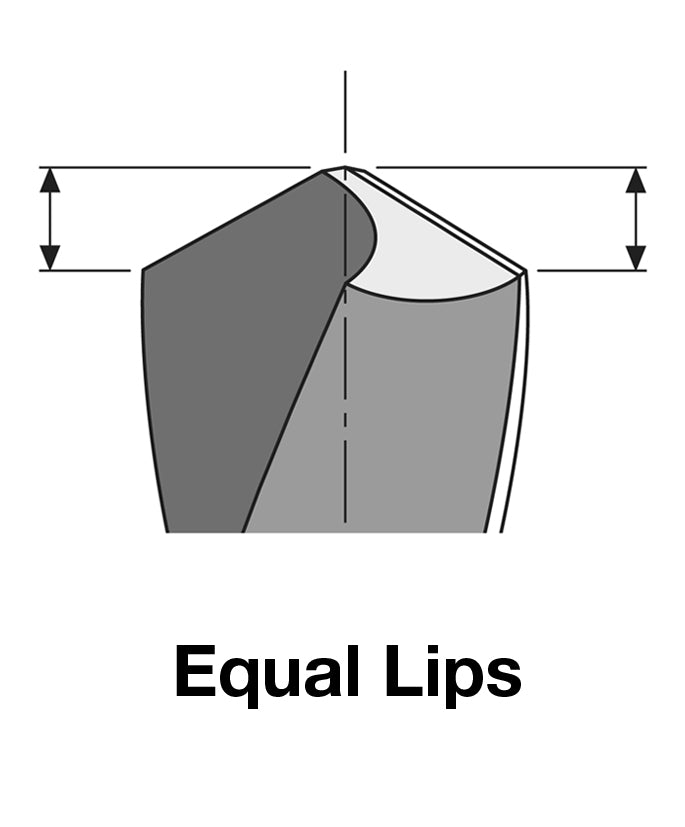

- Sharpens drill bits with outstanding precision.

- Extends drill bit service life more than four times over compared to traditional S-tip drill bits.

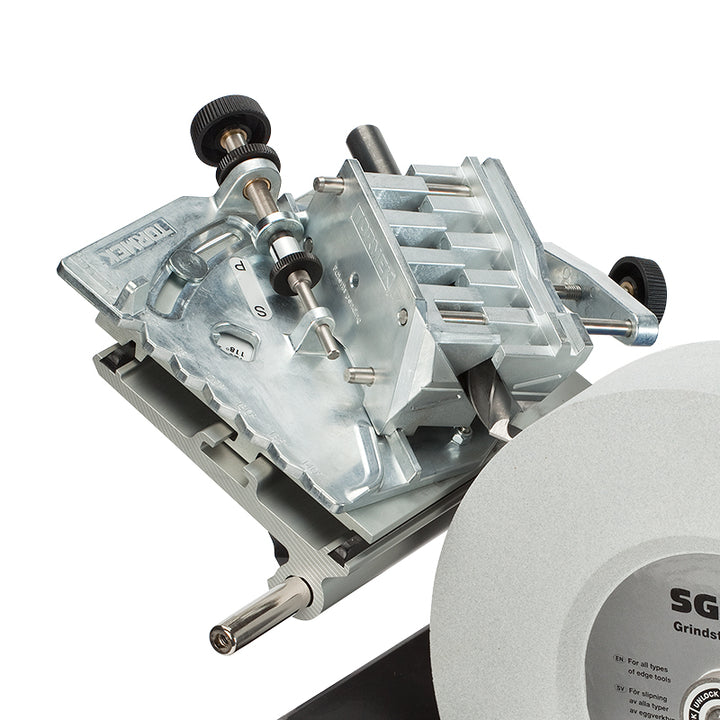

- Works best with Tormek T-8, as well as older models.

Four-facet point that lasts longer

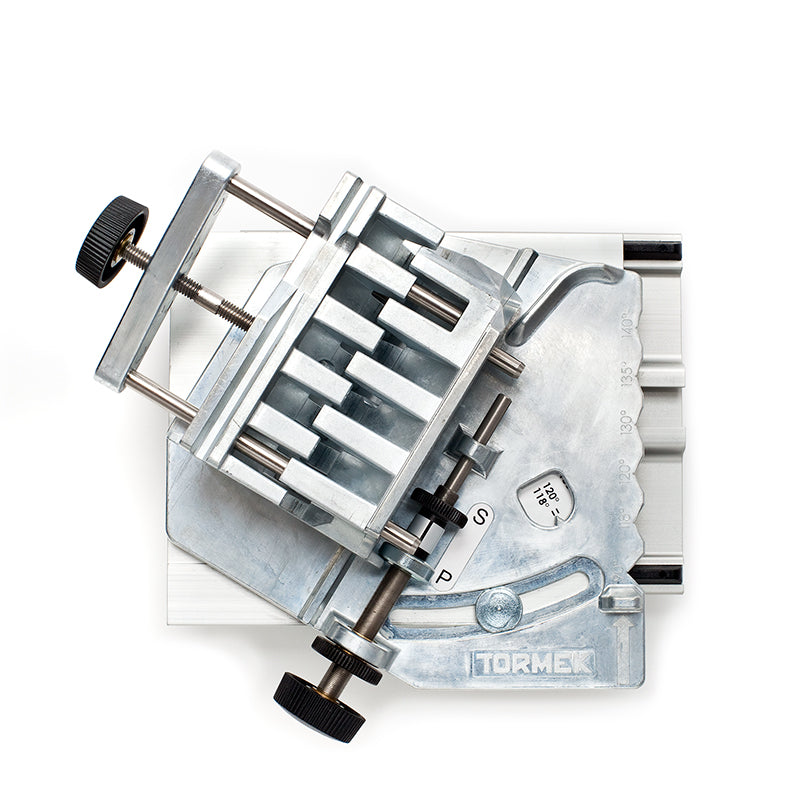

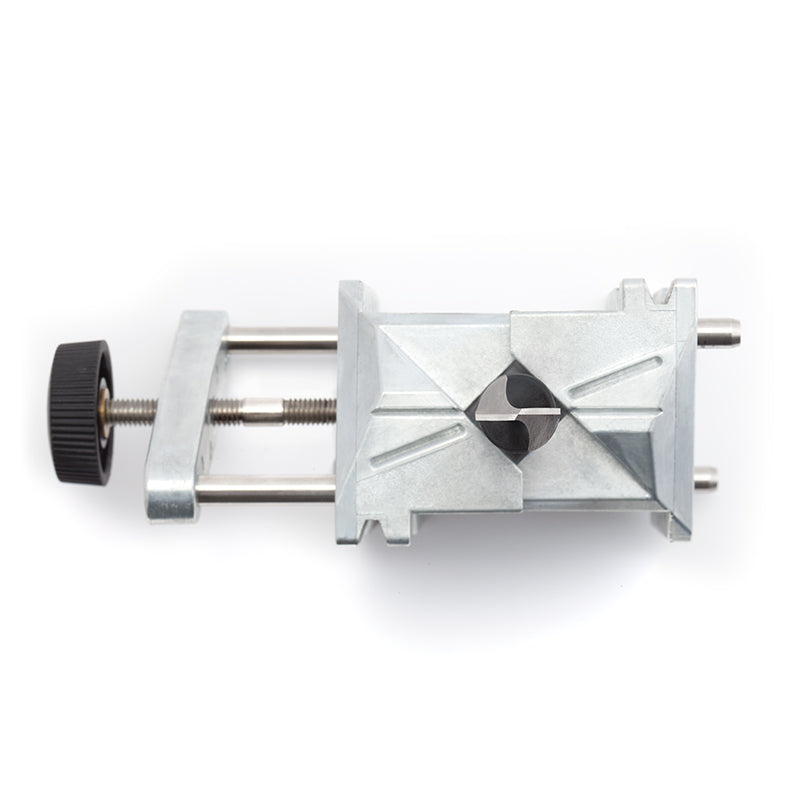

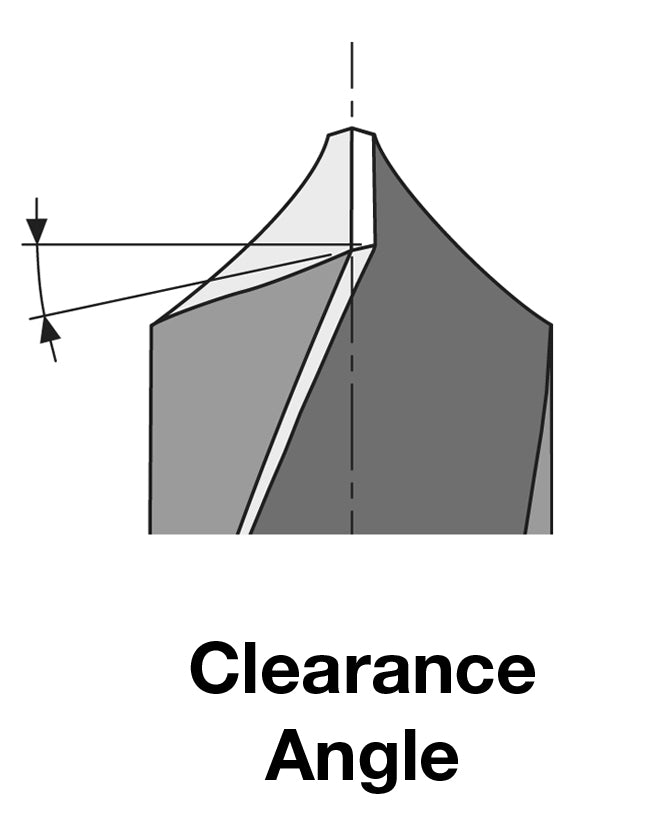

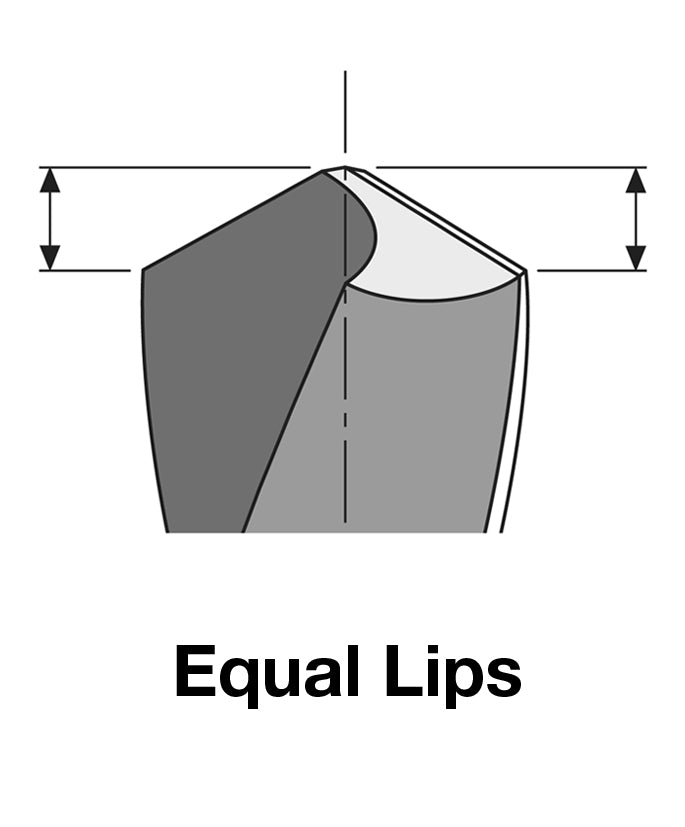

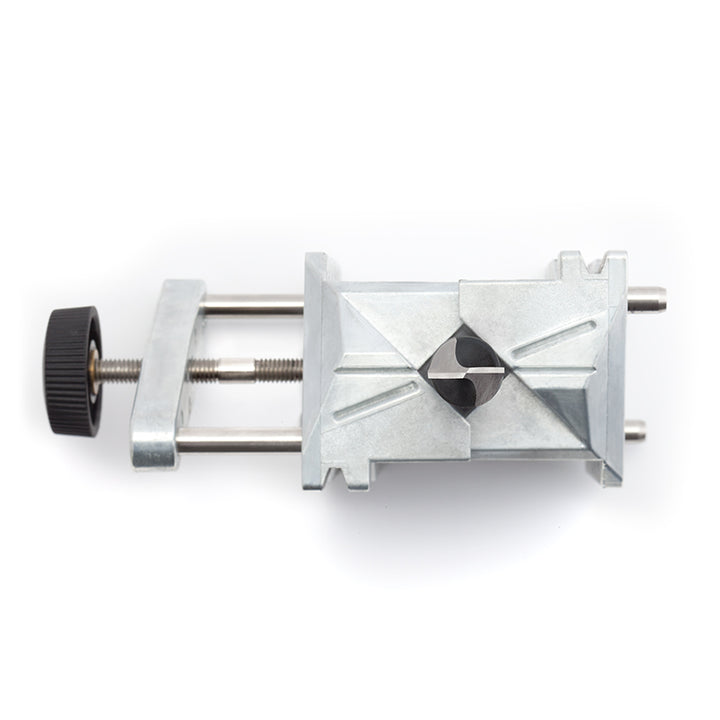

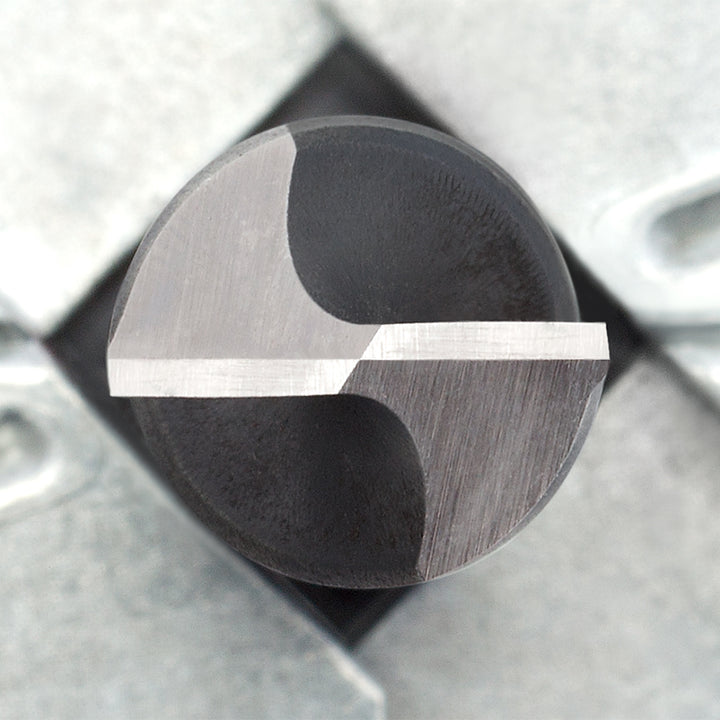

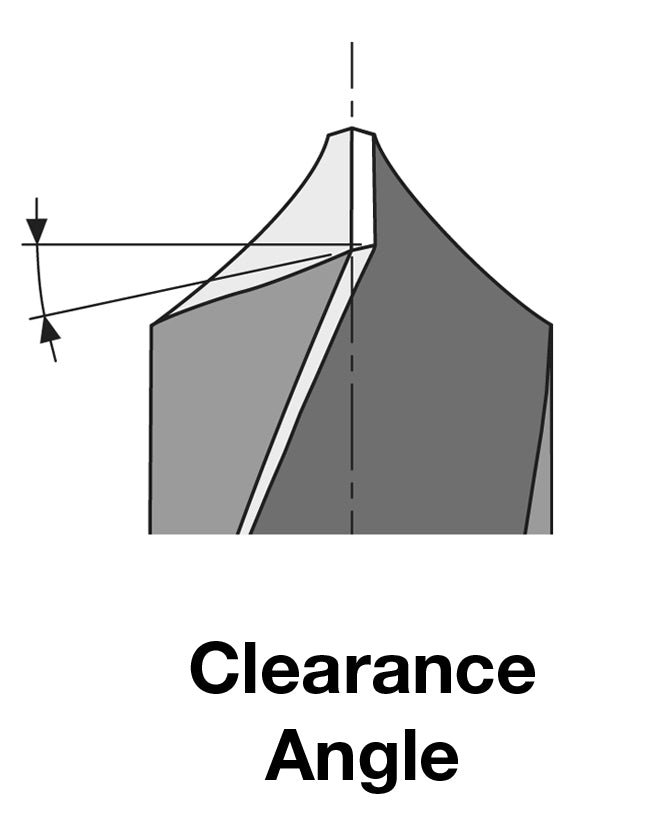

The patented DBS-22 Drill Bit Sharpening Attachment is used to create a four-facet point that provides great cutting characteristics as the cross-cut of the drill bit is pointed instead of being almost flat, as on many other drill bits. A four-facet point won't wander and requires significantly less drilling pressure compared to a conventional cone point drill.

A precision-sharpened four-facet point also reduces heat build-up, giving a very long service life for the drill bit. Independent tests show that drill bits sharpened using Tormek equipment last more than four times longer than new conventional drill bits¹.

¹ Uddeholm Tooling AB, 2010. In the test, 15 mm (0.59") deep holes were drilled in a hardened steel using a 6 mm (0.24") drill bit. At a speed of 1326 rpm and 0.15 mm (0.006") feed per revolution, the drill bits sharpened using the Tormek equipment lasted for 327 holes on average, while the new S-tip drill bits lasted for 72 holes.

Controlled sharpening

The risk of overheating and microcracking or loss of hardening of the steel is eliminated by working with the natural laws and cooling the edge continuously. You have full control at all times and can see how sharpening is progressing. A magnifying glass is included for smaller drill bits to help you line up the bit in the jig and see the results of your sharpening.

Related Products

You may also be interested in