Why BGM-100 Bench Grinder Mounting Set?

- Reshape the tool profile quickly and easily on your bench grinder.

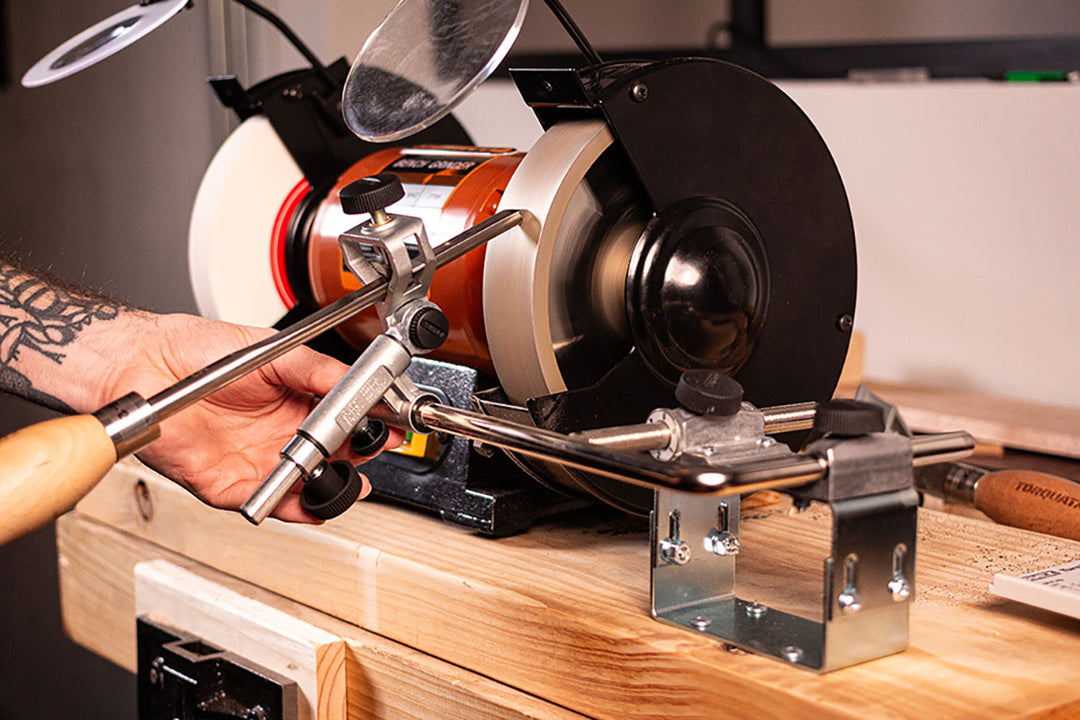

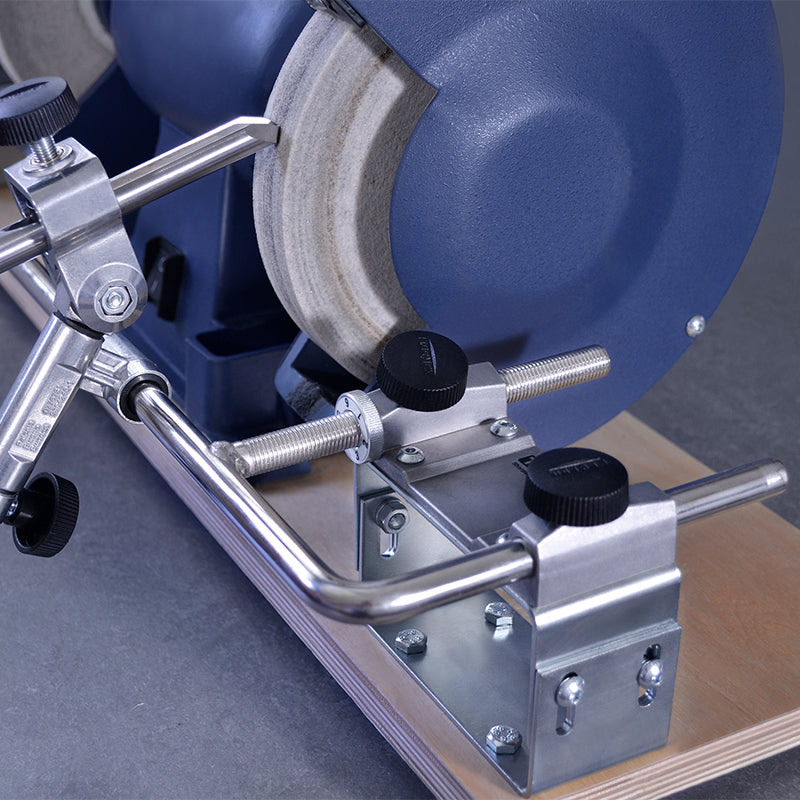

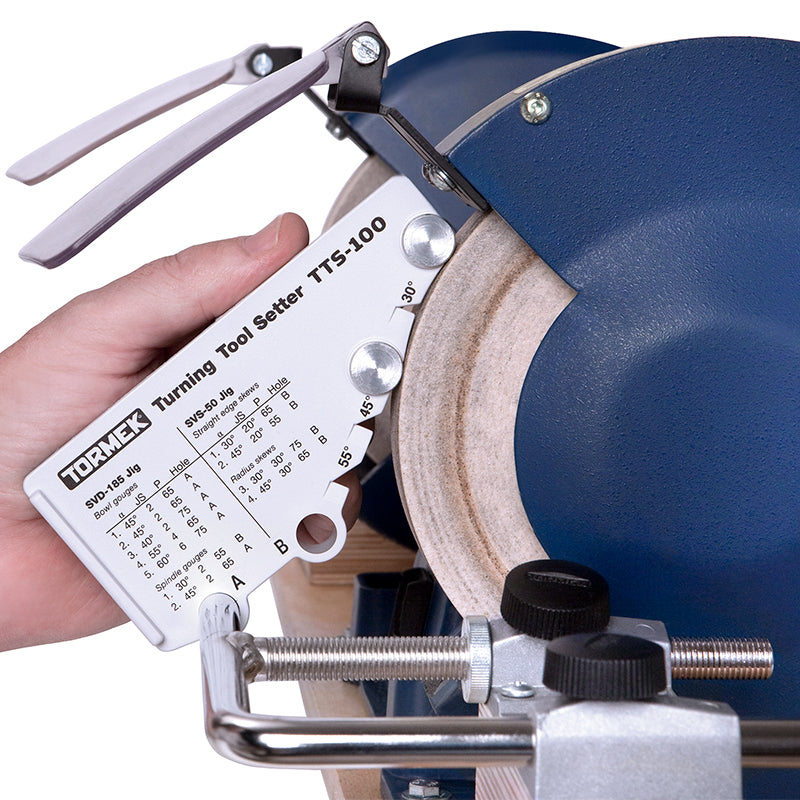

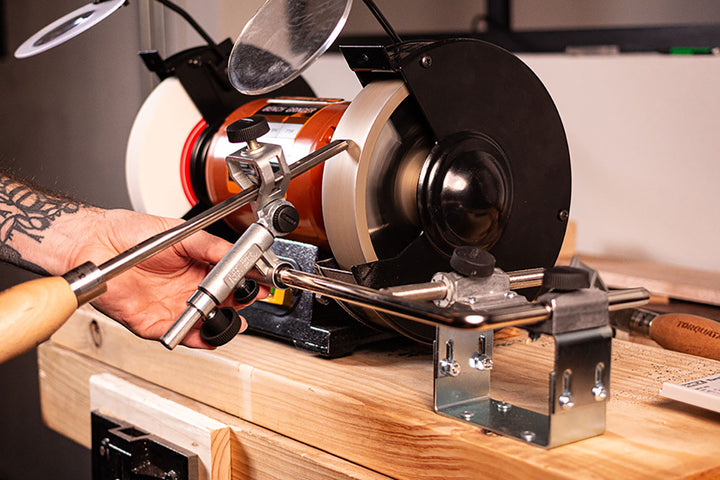

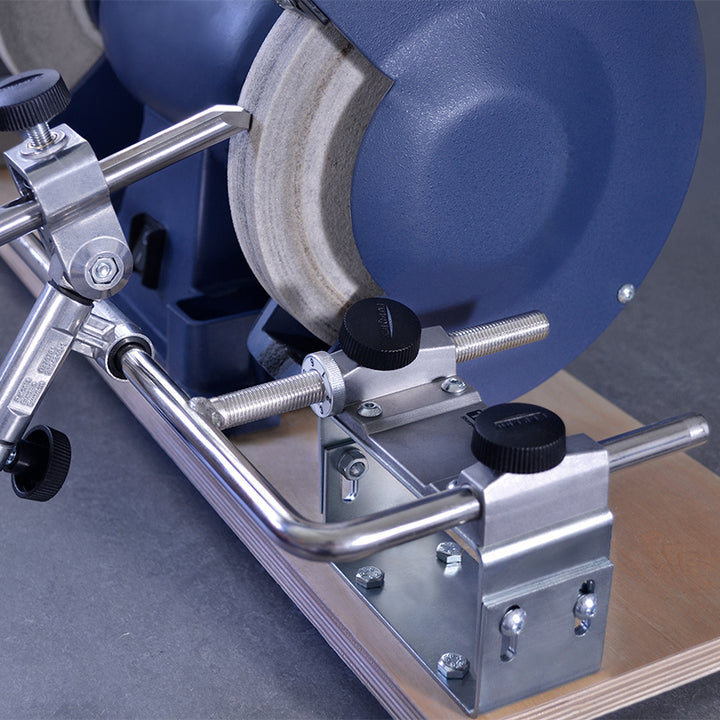

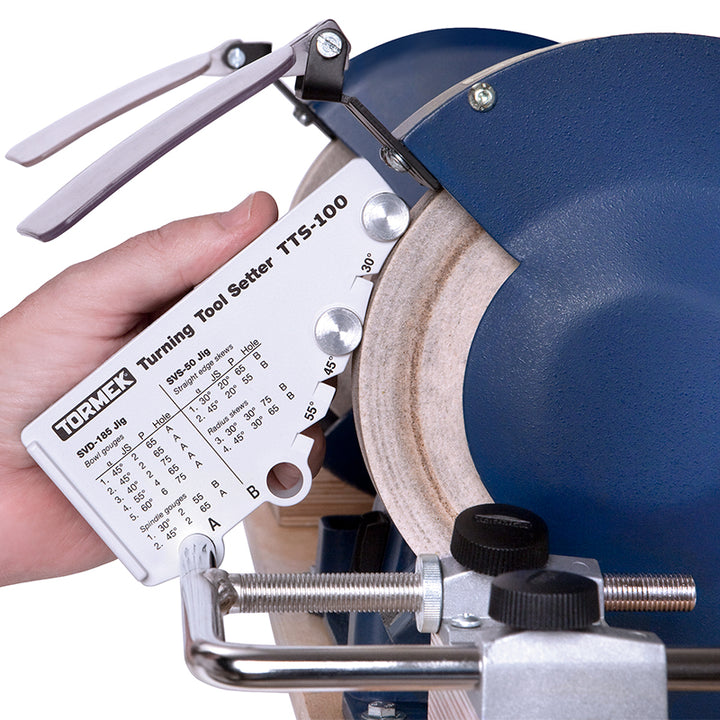

- Allows you to use the SVD-186 R Gouge Jig, SVS-50 Multi Jig, SVD-110 Tool Rest and TTS-100 Turning Tool Setter on your bench grinder.

- Keep the same jig setting when sharpening on your Tormek as when you shaped the tool on the bench grinder.

- Easy to use.

- Works with most standard bench grinders with the correct grinding wheel.

Take control of your profiles

Regardless of the type of sharpening machine you use, the most difficult part of sharpening woodturning tools is accurately repeating the shape and sharpening angle. The BGM-100 Bench Grinder Mounting Set allows you to use the SVD-186 R Gouge Jig, SVS-50 Multi Jig, SVD-110 Tool Rest and TTS-100 Turning Tool Setter on your bench grinder. This allows you to easily repeat your sharpening, over and over again.

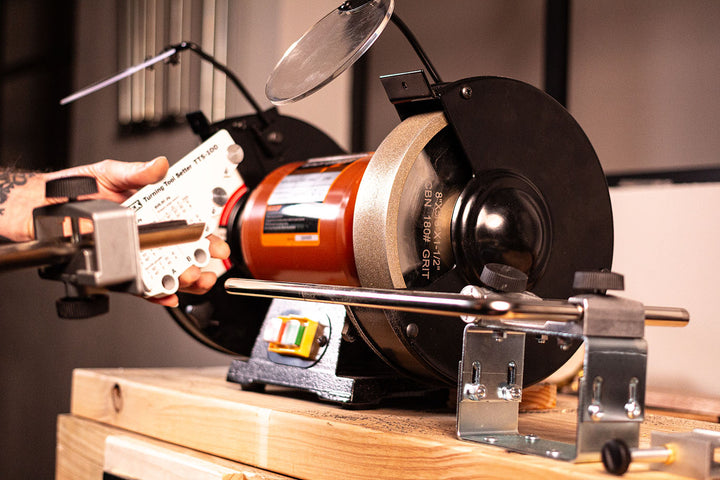

The Tormek water-cooled sharpening system is superior when it comes to sharpening virtually any tool in your workshop. That said, it's no secret that major reshaping of a woodturning tool can be done faster on a bench grinder. Some woodturners who are dedicated Tormek users also have access to a bench grinder and use it together with the BGM-100 Bench Grinder Mounting Set for the first rough shaping operation.

With or without a Tormek machine

With the BGM-100 Bench Grinder Mounting Set, you can use the precise Tormek jigs throughout the grinding process. You no longer need to rely on trial and error to find the right shape using your bench grinder. Thanks to the TTS-100 Turning Tool Setter, you can quickly grind away material on the bench grinder and then move to your Tormek machine – without changing the jig settings – for the final sharpening and honing.

If you don't yet have a Tormek machine, you can still take advantage of Tormek's precise jig system on your bench grinder and easily create the desired shape and angle. The principle of setting the shape and sharpening angle is the same no matter which machine you use. If you later decide to expand your workshop to include a Tormek, then you already have the jigs you need for your woodturning tools.

Which grinding disc for the bench grinder?

Not all grinding discs are suitable for grinding edge tools with precision on a bench grinder. The standard mounted discs are often too hard, so they clog easily and lose their sharpening ability, causing the tool to overheat. Worn abrasive grains have to come off during grinding so that new grains are activated, otherwise the disc will clog and the abrasive grains will slip instead of cutting, increasing friction and generating heat.

Use an aluminum oxide disc with the right bonding – it mustn't be too hard as this would cause burning, and it mustn't be too soft as this would cause grooves. The wheel must be kept fresh and clean. Use a grinding disc dresser as recommended by your machine manufacturer.

The effect of heat on HSS steel

HSS steel can withstand much higher temperatures than carbon steel without losing its hardness. Nevertheless, the temperature in the outermost, very thin, apex of the edge can easily rise to a level that affects hardness and durability. Therefore, grind the tip of the edge carefully and don't let it turn blue.

Overheating HSS steel may reduce hardness by as much as 4 HRC (Rockwell), which drastically shortens edge retention. If you cool the tool in water, avoid abrupt cooling from a high temperature as this can cause microcracks in the edge that are invisible to the eye.

Dealing with grinding dust

The fine dust from the grinding disc and steel particles from the tool can be hazardous to health. It's best to use an extractor to prevent the dust contaminating the air. You have to use a separate dust extractor and not the same system as for the wood dust generated by your woodworking machines, as sparks could ignite the fine wood dust.

Related Products

You may also be interested in